What is the Difference Between Single Block and Bleed and Double Block and Bleed Valves?

In industries that deal with hazardous materials like oil, gas, or chemicals, safety and reliability are critical. The terms single block and bleed and double block and bleed refer to two distinct valve systems. These gate valve types are designed to ensure safety by isolating sections of a pipeline or equipment. These systems are crucial when maintaining, repairing, or testing pipelines. Understanding the differences between these two types of valves can help industries choose the best solution for their needs.

What is a Single Block and Bleed Valve?

A single block and bleed valve is designed to stop the flow of fluids or gases from a single direction and release any trapped pressure.1 The valve consists of one block valve and one bleed valve. The block valve stops the flow of the medium.

The bleed valve releases any residual pressure or trapped fluids between the two valves. This setup ensures that any buildup of pressure is safely vented, preventing accidents or leaks.

The block and bleed valve is typically used in situations where isolating one side of a system is sufficient. These valves are often installed in smaller, less critical systems where full isolation on both sides is not necessary.

What is a Double Block and Bleed Valve?

A double block and bleed valve (commonly abbreviated as DBB valve) is a system designed to completely isolate a section of a pipeline from both sides. It has two block valves and one bleed valve. The double block and bleed valve ensure complete isolation of the system. It is done by stopping the flow from two directions and safely releasing any trapped pressure through the bleed valve. This setup is essential when working with hazardous materials. Safety and leak prevention are critical.

The double block and bleed valve is commonly used in industries like oil and gas, where even a small leak can pose significant safety risks. The DBB meaning (double block and bleed) refers to the system’s ability to provide dual isolation with pressure release. They offer a higher level of safety compared to single block and bleed systems.

Key Differences Between Single Block and Bleed and Double Block and Bleed

The primary difference between single block and bleed and double block and bleed systems is the number of block valves used and the level of isolation they provide. Below are the main distinctions:

Number of Block Valves

- Single Block and Bleed: Contains one block valve and one bleed valve.

- Double Block and Bleed: Has two block valves and one bleed valve.

Level of Isolation

- Single Block and Bleed: Provides isolation in one direction. Meaning it stops the flow from one side of the system while allowing pressure release.2

- Double Block and Bleed: Offers complete isolation on both sides. It prevents flow from both directions and allows for pressure release between the block valves.2

Application

- Single Block and Bleed: Used in simpler, less critical systems where isolation on one side is enough.2

- Double Block and Bleed: Necessary in high-risk environments where full isolation is essential to prevent accidents and ensure safety.2

Definition DIB: What is DIB?

The DIB definition refers to Double Isolation and Bleed. Similar to DB&B, DIB systems provide two independent seating surfaces for isolation. The difference is that DIB systems offer more flexibility by allowing one seat to function as an emergency backup. In a DIB valve, one of the seats could act as a secondary seal, which is beneficial in cases where one seat might fail.

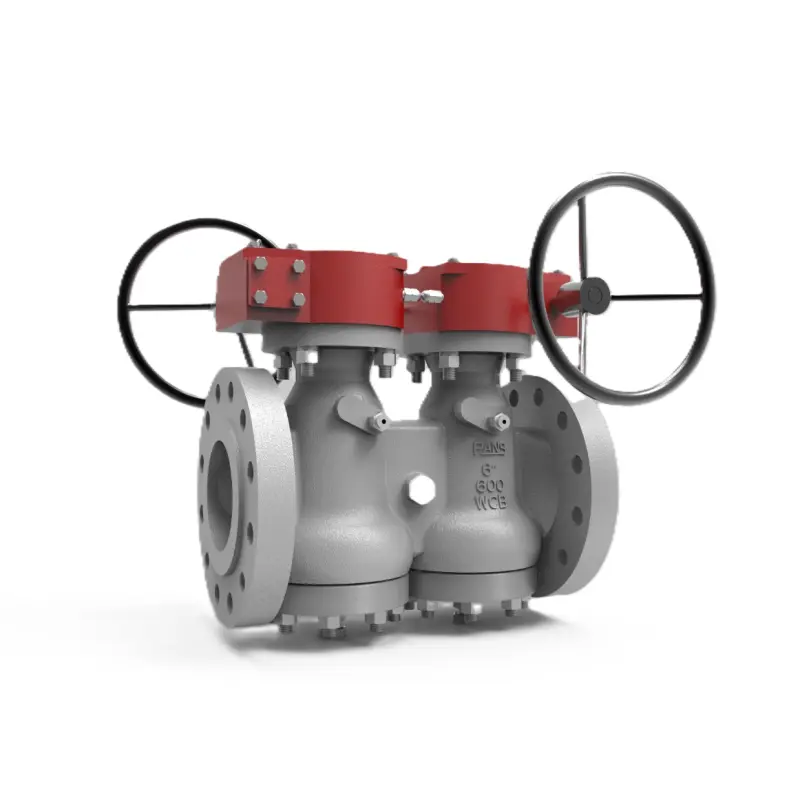

Features of Double Block and Bleed Valves by PANS Valve

When selecting a DBB valve, quality and reliability are key. PANS Valve, a professional valve manufacturer, offers high-quality double block and bleed valves designed for safety and efficiency. Below are some of the main features of their double block and bleed solutions:

Double Sealing for Hazardous Materials

PANS Valve’s double block and bleed valves are perfect for handling hazardous materials such as aviation kerosene, natural gas, and liquefied petroleum gas. These materials are highly flammable. PANS Valve uses a middle flange with a double seal structure. The O-ring and winding gasket provide extra protection against leaks.

Durable Materials and Corrosion Resistance

Key parts of the valve, such as the valve body cavity and slide block, are processed and coated to resist corrosion, erosion, and wear. This makes the valves more durable and long-lasting, even in tough environments.

Pressure Relief Systems

PANS Valve offers three different pressure relief systems for double block and bleed valves. These include:

– Manual pressure relief for manual operation.

– Differential pressure relief for both manual and electric operation.

– Automatic pressure relief for electric valves. This ensures that any pressure buildup in the valve cavity is safely vented, preventing damage or accidents.

Flexible Operation

The double block bleed valve from PANS Valve features an L-shaped slot structure in the operating mechanism. This allows the valve to operate flexibly, with smooth movement and easy handling.

Low Maintenance

The valve includes a window for online adjustment and maintenance of the packing. This reduces downtime and ensures that the valve remains safe and functional during operation.

Why Choose PANS Valve?

For over 36 years, PANS Valve has been a trusted name in the valve industry. Their products are known for their durability, high-quality manufacturing, and safety features. Some of the key reasons to choose PANS Valve for your DBB valve needs include:

- 5 Manufacturing Bases: PANS Valve has an extensive production capacity with over 25,000 square meters of workshop space.

- High Output: With an annual production of over 3,000 tons of valves, they can meet the demands of large-scale industrial projects.

- Fast Turnaround: Customers can expect to receive quotes and drawings within 24 hours. In addition, PANS Valve can deliver most products within 20 days, thanks to its large stock of rough embryos.

- One-Stop Solution: PANS Valve offers a wide range of valves, including plug valves, ball valves, globe valves, gate valves, and more. They can meet the needs of any industrial project.

Conclusion

Understanding the difference between single-block and bleed and double-block and bleed valves is important for industries that require reliable safety measures. Single block and bleed valves provide basic isolation from one side. Double block and bleed valves offer complete isolation from both sides, making them ideal for high-risk environments.

If you’re looking for high-quality DBB valves, PANS Valve provides a robust solution. Their valves are durable, reliable, and designed with safety in mind. They are perfect for industries handling hazardous materials. Whether you need a valve for aviation kerosene, natural gas, or liquefied petroleum gas, PANS Valve has the expertise and product range to meet your needs.

References

1.What is SBB Ball Valve and How it Works

(https://www.dombor.com/what-is-single-block-and-bleed-valve/)

2.Block and Bleed Valve Function

(https://chemicalengineeringworld.com/block-and-bleed-valve-function/)

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer