Floating Ball Valve vs Trunnion Ball Valve: What is the Difference?

The key difference between floating ball valves and trunnion ball valves lies in how the ball is supported.

For context, the ball is not fixed (“floats”) in floating ball valves, which means it relies on fluid pressure to push it against the downstream seat for sealing.

Meanwhile, trunnion ball valves reduce seat stress and allow smoother operation under high pressure because a trunnion anchors the ball.

To understand each of these valves better, this article talks about key differences in applications and working principles.

Floating Ball Valves: Definition

A floating ball valve is a quarter-turn type of valve where the ball is not supported by a trunnion and floats when fluid pressure is applied.

The ball presses against the valve seats to form a tight seal.

How Floating Ball Valves Work

Two valve seats hold the ball in place. However, the ball is not physically secured.

When the ball moves slightly, it allows the fluid pressure to push it into the downstream seat, creating a tight seal.

When the handle is turned 90 degrees, the ball rotates, either allowing or blocking the flow of fluid.

Components of Floating Ball Valves

- Body: The outer shell that houses the internal parts.

- Ball: The key component that rotates to control flow.

- Seats: Positioned on both sides of the ball to ensure sealing.

- Stem: Connects the ball to the actuator or handle.

- Handle/Actuator: Allows manual or automatic operation of the valve.

Features of Floating Ball Valves

#1. Compact design

Floating ball valves are typically smaller and more compact than trunnion ball valves. This makes them ideal for applications where space is limited.

#2. Effective for low to medium pressures

They perform well in low to medium-pressure systems, which provide excellent sealing capabilities.

#3. Simple structure

Fewer components make maintenance and installation easier.

Drawbacks to Consider

#1. Higher torque required

The design requires more torque to operate, especially at higher pressures, which can wear out the seats more quickly.

#2. Pressure limitations

Floating ball valves are not suitable for very high-pressure applications because the ball is entirely dependent on the seat for sealing.

Trunnion Ball Valves: Definition

A trunnion ball valve differs from a floating ball valve in that the ball is anchored by a trunnion (a type of pin or shaft).

This design allows the ball to stay in place even when high pressure is applied, making it suitable for high-pressure applications.

How Trunnion Ball Valves Work

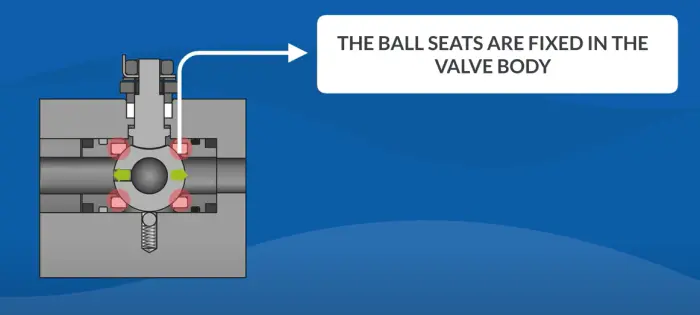

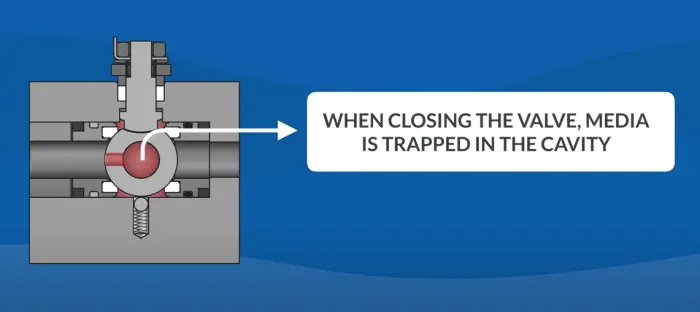

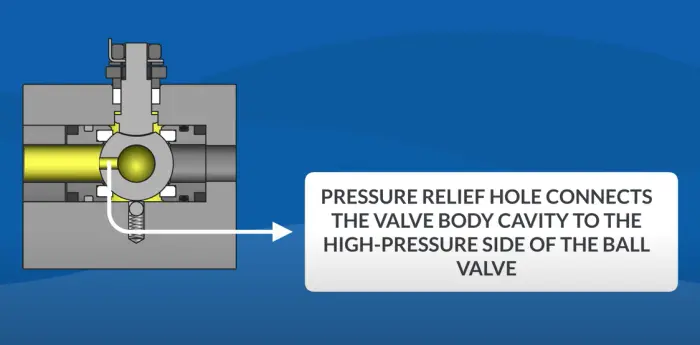

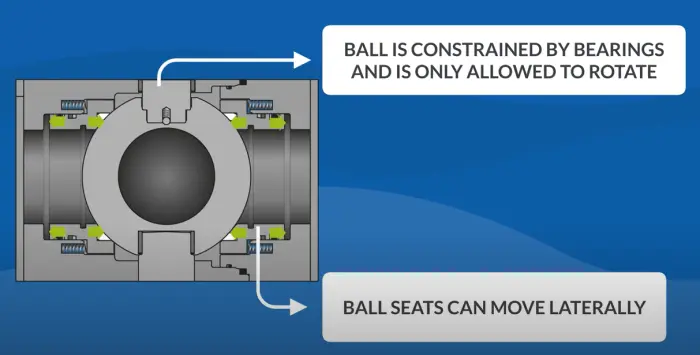

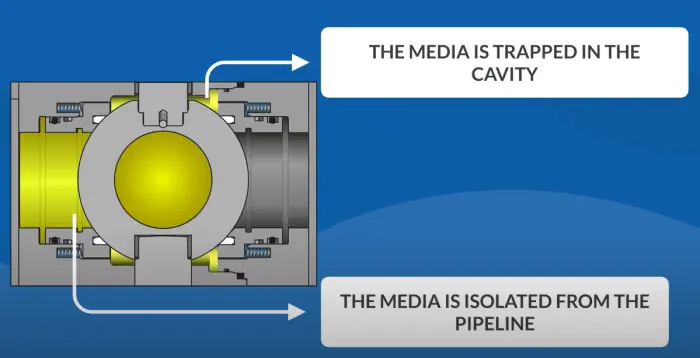

In trunnion ball valves, the ball is fixed in place by a trunnion, with the seats moving to form the seal.

This reduces the stress on the seats, allowing for smooth operation even under high pressure. The valve opens or closes by rotating the ball with a 90-degree turn of the handle or actuator.

Components of Trunnion Ball Valves

- Body: The external casing that houses all internal components.

- Ball: Held securely in place by the trunnion.

- Seats: Pressed against the ball by springs or other mechanisms to create a tight seal.

- Stem: Connects to the ball to control its movement.

- Trunnion: A mechanical anchor that supports the ball and reduces its movement.

- Handle/Actuator: Controls the movement of the ball for opening and closing.

Features of Trunnion Ball Valves

#1. Suitable for high-pressure applications

Trunnion ball valves are built to handle high pressures without compromising sealing performance.

#2. Lower operating torque

Since the ball is fixed, it requires less torque to operate, reducing wear and tear on the valve.

#3. Longer lifespan

Due to less stress on the seats, these valves have a longer service life compared to floating ball valves.

Drawbacks to Consider

#1. Complex design

The trunnion ball valve has more components, which can make maintenance and repairs more complex.

#2. Higher cost

Due to the increased complexity and material needs, trunnion ball valves are typically more expensive than floating ball valves.

Floating Ball Valve vs Trunnion Ball Valve: The Difference in Applications

| Criteria | Floating Ball Valve | Trunnion Ball Valve |

| Pressure Range | Low to medium-pressure | Suitable for high-pressure applications |

| Torque Requirements | Higher torque needed for operation | Lower torque is needed due to ball anchoring |

| Size | More compact | Generally larger due to additional components |

| Sealing Mechanism | Relies on fluid pressure to create a seal | Seats move to seal the ball in place |

| Maintenance | Easier due to fewer parts | More complex, requiring detailed maintenance |

| Cost | More affordable | More expensive due to the complex design |

How to Choose the Right Valve for Your Needs

Selecting between a floating ball valve and a trunnion ball valve depends on the specific requirements of your application. Here are some factors to consider:

#1: Pressure levels

If you’re dealing with low to medium pressure, a floating ball valve is likely sufficient. For high-pressure systems, a trunnion ball valve is the better option.

#2: Torque concerns

If ease of operation is important, especially in high-pressure environments, trunnion ball valves are easier to operate due to lower torque requirements.

#3: Space constraints

Floating ball valves are more compact, making them ideal for tight spaces.

#4: Budget

Floating ball valves tend to be more cost-effective, while trunnion ball valves offer more durability at a higher cost.

Finding Floating and Trunnion Ball Valve Manufacturers

One of the leading manufacturers of ball valves is Zhejiang Zhedong Valve Corp., Ltd, also known as PANS Valve.

Established in 1985, the company has over 30 years of professional experience in producing a wide range of steel valves, including floating and trunnion ball valves.

Recommended Products:

Located in Wenzhou, China, PANS Valve operates out of a modern industrial park spanning 25,000 square meters and employs over 200 skilled workers.

With an annual production capacity of 3,000 tons, PANS Valve ensures a consistent supply of high-quality valves for various industries, including petroleum, chemical, power, and natural gas sectors.

Moreover, PANS Valve is renowned for its commitment to producing industrial valves that meet or exceed international standards.

With 60 valve series and over 100 patents, the company is a key member of major industry associations like CNPC and CPAC.

PANS Valve has successfully partnered with clients in over 60 countries, delivering customized solutions for industry leaders across Europe, America, and Asia.

- What is a Floating Ball Valve? How Does it Work?

- Understanding Trunnion Ball Valves: A Comprehensive Guide

- ”How ” link=”https://www.geminivalve.com/floating-ball-valves-vs-trunnion-ball-valves/”]

- Floating Ball Valve Vs. Trunnion: What's Their Difference

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer