What is a pressure seal gate valve?

A pressure seal gate valve refers to a specialized valve designed for high-pressure and high-temperature applications. One of its unique features includes a pressure seal gate valve design. It enhances the sealing effectiveness of the valve as internal pressure increases.

Pressure seal gate valves have crucial applications in several industries where the seal’s integrity is paramount. Thus, it ensures safe and efficient operations under extreme conditions.

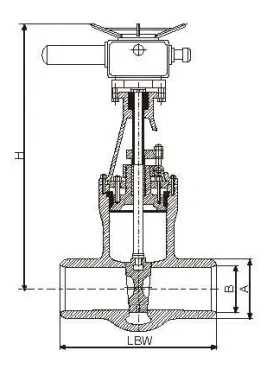

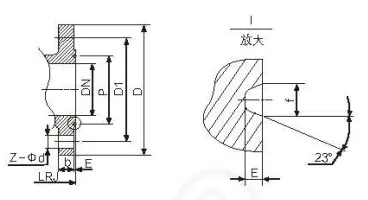

Pressure Seal Gate Valve Design

The structure of a pressure seal gate valve is distinct from conventional gate valves. Below are the components of a pressure seal gate valve:

Pressure Seal Bonnet

The hallmark of a pressure seal gate valve is the pressure seal bonnet. It uses internal pressure to create a tighter seal. When pressure increases, the bonnet gasket is compressed more firmly. This quality improves sealing performance.

Gate

Typically a solid wedge, this component moves perpendicular to the flow direction to open or close the valve. Several types of gate designs are available: Wedge Gate, Slab Gate, and Knife Gate.

Stem

This component could be rising or non-rising. It connects the gate and controls its movements. Rising stems visually indicate the valve’s position, whereas non-rising stems are used where space is limited.

Body and End Connections

Made from high-strength materials like carbon steel or stainless steel, the body is designed to withstand harsh conditions. End connections, on the other hand, can be flanged or butt-welded.

Pressure Searl Gate Valve PDF Download >>

Pressure Seal Gate Valve Pros and Cons

Just like any other industrial-grade steel valve, the pressure seal gate valve has its own set of advantages and disadvantages:

Pros

#1 Minimal fluid resistance

A major benefit of pressure seal gate valves is their low resistance to fluid flows.

#2 Effective sealing

A pressure seal gate valve is renowned for its exceptional sealing quality.

#3 Versatile applications

This type of gate valve has several applications: steam, oil, various fluids, and mediums with high viscosity containing granular solids.

#4 Bidirectional flow

Pressure seal gate valves allow fluid to flow in both directions. This quality makes the valve ideal for applications where the flow direction changes.

Cons

#1 High friction and wear

The sealing surfaces can become damaged due to the friction encountered during valve operation.

#2 Large installation size

Despite offering a larger opening size, pressure seal gate valves also have a greater overall height. Such a feature can complicate its installation.

Application Scenarios of Pressure Seal Gate Valves

> Power Generation

> Petrochemical and Refinery

> Oil and Gas

> Chemical Industry

Introducing PANS: Manufacturer of Pressure-Sealed Gate Valves

PANS is a leading manufacturer of industrial-grade steel valves. As a reputable China pressure seal gate valve factory, PANS offers a wide range of products designed to meet the rigorous demands of industrial applications.

PANS’ valves are famous for their durability, reliability, and superior performance. They offer wholesale pressure seal gate valve products to industries in need of their services.

Click Here to Request a Quote! >>

- Valves by Roy A. Parisher, Robert A. Rhea, in Pipe Drafting and Design (Fourth Edition), 2022

- Research on Gate Valve Internal Leakage Detection Based on Acoustic Emission Signal Processing; Liang Zhu, Bin Zou, Shao Hua Gao, Ming Jiang, Zhi Ping Li

- Hydraulic analysis of gate valve using computational fluid dynamics (CFD); October 2020 Scientific Review Engineering and Environmental Sciences (SREES)

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer