What Is a DIN Rising Stem Gate Valve?

A DIN rising stem gate valve is a type of industrial valve used to control the flow of liquids or gases by lifting a gate out of the flow path. It features a rising stem that visibly moves up and down as the valve opens and closes, making it easy to identify the valve’s position. The “DIN” in its name refers to Deutsches Institut für Normung, which is the German national standard for valve manufacturing, ensuring quality, dimensions, and compatibility.

In this article, we’ll explore what makes a rising stem gate valve unique, how it works, when it’s used, and what to know about DIN specifications, dimensions, and technical drawings. Whether new to industrial valves or looking to make a smarter purchasing decision, this breakdown will keep things clear and practical.

🧠 Quick Takeaways: What Is a DIN Rising Stem Gate Valve?

- A DIN rising stem gate valve controls flow by lifting a disc (or gate) using a stem that visibly rises and lowers.

- It follows DIN standards for design, materials, and measurements, widely used across Europe and global projects for quality assurance.

- These valves are ideal for on/off isolation in pipelines—especially when visual valve status is important.

How a Rising Stem Gate Valve Works

A rising stem gate valve uses a straightforward vertical motion to control flow. Turning the handwheel moves the stem up or down, which lifts or drops the internal gate. This design gives a clear visual cue—if the stem is up, the valve is open; if it’s down, it’s closed.

Unlike a non-rising stem valve, the gate valve with a rising stem has a design that allows operators to visually confirm whether the valve is open or shut without needing additional instrumentation. That’s one reason it’s often found in high-stakes industrial systems where valve position visibility is essential.

Why “DIN” Matters: What Does DIN Mean in Valve?

DIN stands for Deutsches Institut für Normung, the German Institute for Standardization. A DIN valve follows precise standards for dimensions, pressure ratings, flange types, material quality, and more.

For example, a DIN rising stem gate valve ensures:

- Interchangeability with other DIN-compliant components

- Quality control under strict manufacturing guidelines

- Standardized rising stem gate valve dimensions, so parts can be matched across vendors

This is especially important in European, Middle Eastern, and global projects that require consistency and safety in pipeline systems.

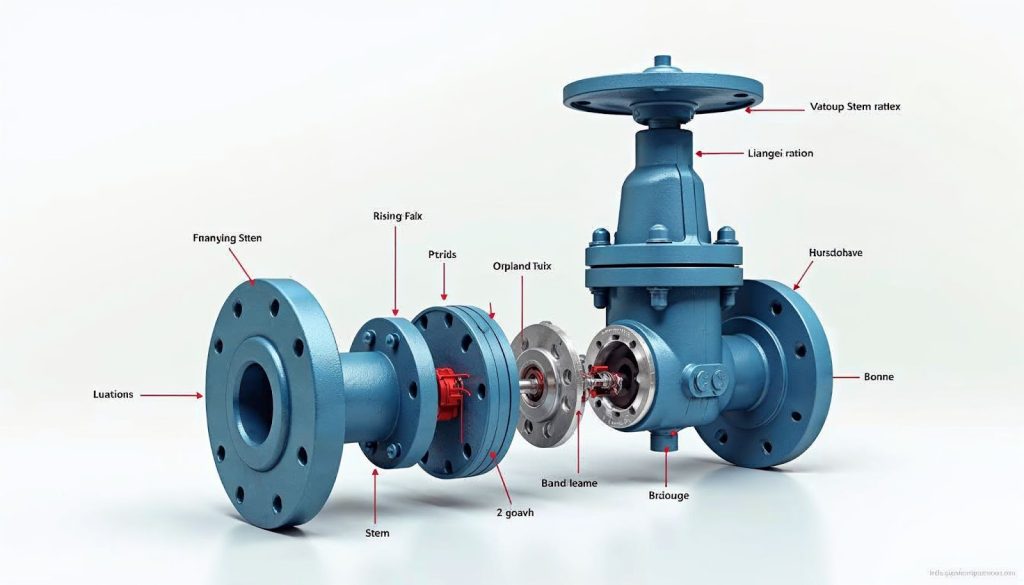

Key Features of a DIN Rising Stem Gate Valve

Let’s break down the core elements that define this valve type:

- External Threaded Stem

The stem is located outside the valve body, making the threading accessible for easy lubrication and maintenance. This is especially helpful in harsh industrial environments where smooth operation is crucial.

- Visual Valve Status

Operators can easily tell if the valve is open or closed by looking at the stem height—this is a big advantage over concealed designs.

- Full Bore, Minimal Pressure Drop

When the valve is open, the gate is fully out of the flow path. This reduces pressure drop and turbulence, preserving energy efficiency.

- Designed for Isolation, Not Throttling

This valve is perfect for fully open or fully closed operation. It’s not ideal for regulating flow since partial openings can cause uneven wear on the gate.

Where Is a DIN Rising Stem Gate Valve Used?

This valve is a favorite across many industries for on/off control in pipelines carrying water, oil, gas, steam, and other fluids. You’ll find it in:

- Water treatment plants

- Power generation

- Oil & gas pipelines

- Petrochemical processing

- Industrial utility systems

Its ability to handle high-pressure and temperature environments and clear open/closed indicators makes it a reliable choice for safety-critical operations.

Advantages Of Non-Rising Stem Valves

While non-rising stem gate valves are often more compact, especially in underground or space-constrained installations, the rising stem design offers benefits such as:

- Easier maintenance due to external threading

- Visual confirmation of valve status

- Reduced risk of internal thread corrosion

- Simpler actuator integration

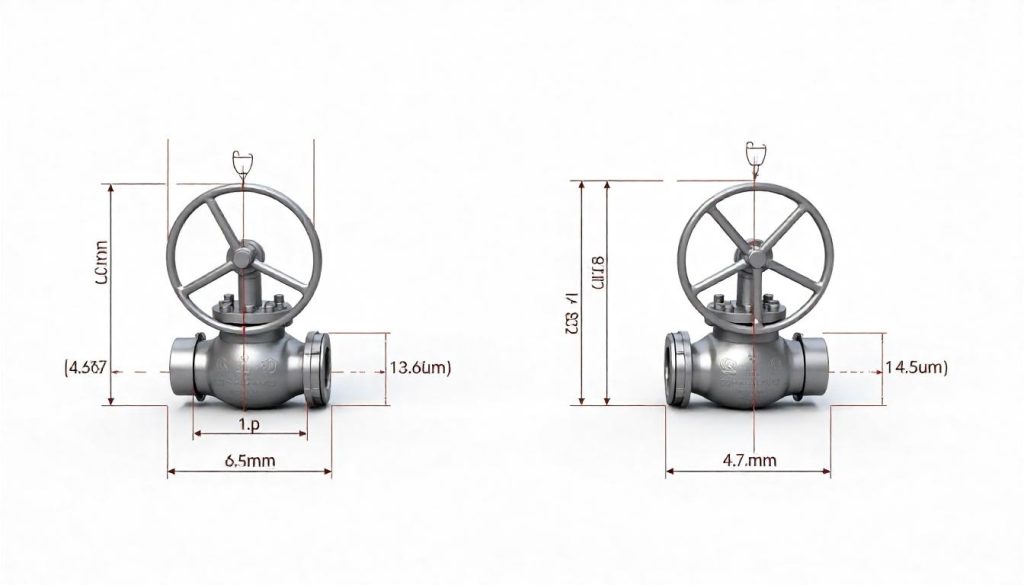

DIN Rising Stem Gate Valve Dimensions: What You Need to Know

Standard DIN rising stem gate valve dimensions ensure compatibility across equipment. These measurements define:

- Face-to-face length

- Flange diameter and bolt holes

- Valve body height (including extended stem)

- Stem travel distance

This dimensional accuracy is essential when replacing or upgrading valves in pre-existing systems. DIN standards like EN 558-1 Series 14 or DIN 3202 are commonly used references.

Understanding the DIN Rising Stem Flanged Gate Valve

A rising stem flanged gate valve refers to a valve with flanged ends that bolt directly into pipelines. DIN flanges are typically defined under DIN EN 1092-1, ensuring consistent bolt patterns, pressure classes, and gasket dimensions.

Benefits of DIN flanged valves:

- Secure, leak-resistant connections

- Easy disassembly for maintenance

- Better suited for high-pressure systems

Can I Find a DIN Rising Stem Gate Valve Drawing?

Yes. Most DIN-compliant manufacturers—like PANS VALVE—provide technical drawings or CAD files for their products. These show:

- Valve dimensions

- Flow direction

- Material specifications

- Stem travel distances

- Flange drilling patterns

These files are essential for engineering teams planning detailed system layouts or requiring official documentation.

Final Thoughts: Choose Smarter with PANS VALVE

Understanding how a DIN rising stem gate valve works gives you the power to make better decisions for your next project. From visual position indicators to DIN-standard compatibility, this valve is a solid, reliable choice for engineers, project managers, and system designers alike.

At PANS VALVE, we specialize in DIN-compliant industrial valves, including gate, globe, ball, and check valves. With over 36 years of manufacturing excellence, five production bases, and strict ISO/API certifications, we offer fast quotes, custom solutions, and expert support for your global pipeline needs.

👉 Explore Our Products

👉 Request a Quote in 24 Hours

Resources

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer