What’s the Difference Between NRS and OS&Y Gate Valves?

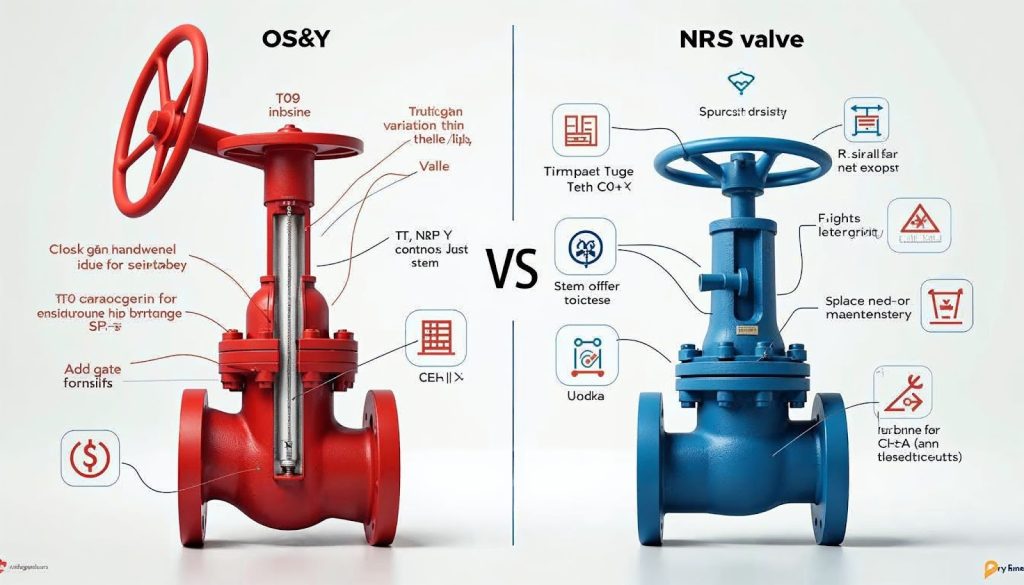

When comparing OS&Y gate valves vs. non rising stem (NRS) gate valves, the difference comes down to how the valve stem moves—and why that matters for safety, maintenance, and visibility. Simply put, OS&Y valves have a rising stem, you can see, while NRS valves keep the stem hidden inside. Each serves a purpose, depending on the application.

This article lists the design, function, pros and cons, and where each type works best. Whether in fire protection, waterworks, or industrial systems, this guide will help you confidently choose between an OS&Y gate valve and an NRS gate valve.

Gate Valve Basics: What They Do and Why They Matter

Gate valves are shut-off valves that control flow by lifting a gate out of the fluid path. When fully open, they allow for minimal pressure loss. When closed, they offer a tight seal.

These valves are common in water supply systems, fire protection lines, oil and gas facilities, and more. Their simple design makes them reliable—but choosing the right stem type (OS&Y vs NRS) is crucial.

What Is an OS&Y Gate Valve?

Quick Summary:

- OS&Y meaning: “Outside Screw and Yoke.”

- Stem Location: Outside the valve body

- Visual cue: The rising stem shows if the valve is open or closed

An OS&Y gate valve has a threaded stem located outside the body. As the wheel is turned, the stem visibly rises or lowers, moving the internal gate. This design makes it easy to see the valve position at a glance.

What are rising stem valves? Rising stem valves like OS&Y are preferred when you need frequent monitoring, such as fire protection systems or industrial pipelines.

Is an OS&Y valve open when the stem is up? Yes. When the stem is raised, the valve is open. When it’s lowered, it’s closed. This helps quickly assess the status during inspections.

What Is a Non Rising Stem (NRS) Gate Valve?

Quick Summary:

- NRS gate valve: Stem stays inside the body

- Space-saving: Ideal where vertical clearance is limited

- Harder to tell: Valve position isn’t visible externally

In an NRS gate valve, the stem doesn’t rise outside. Instead, it turns in place inside the body to raise or lower the gate. Since you can’t see the stem move, it’s harder to know if the valve is open or closed without indicators.

NRS gate valves are often used in underground water lines or tight mechanical rooms where space is at a premium.

OS Y Gate Valve vs. Non Rising Stem: Key Differences

| Criteria | OS&Y Gate Valve | NRS Gate Valve |

| 1. Stem Visibility and Operation | The external stem rises or falls; it clearly shows an open/closed position | Internal stem remains stationary; no visible cue for valve position |

| 2. Installation Space | Requires more vertical clearance due to rising stem | Compact design; ideal for underground or confined installations |

| 3. Maintenance Needs | It is easier to inspect and lubricate due to the exposed stem | Stem is internal and exposed to flow; it requires more frequent maintenance |

| 4. Application Suitability | Best for: – Fire protection systems– Visible operation–High-pressure/high-temp use | Best for: – Submerged/buried lines– Water & wastewater systems– Limited space |

| 5. Durability and Exposure | External threads may be prone to damage without proper protection | Internally located stem is safer from external impact but more vulnerable to internal wear |

Advantages and Disadvantages

OS&Y Gate Valve

Advantages:

- Visible stem makes operation status easy to confirm

- Reduced internal wear since the stem is not exposed to flow

- Easier to maintain and repair

Disadvantages:

- Taller height makes it unsuitable for confined spaces

- The exposed stem may require additional protection outdoors

NRS Gate Valve

Advantages:

- Compact design fits tight or underground areas

- Less prone to accidental damage from external factors

Disadvantages:

- There is no way to know if the valve is open or closed without an indicator

- Stem threads wear faster due to contact with the fluid

- Maintenance and lubrication are more difficult

Where Each Valve Is Mostly Used

What is the OS&Y stem used mostly for?

- Fire sprinkler systems

- Steam systems (Why are OS&Y valves used in steam systems? Because their exposed stems reduce the risk of thread damage from steam corrosion.)

- Industrial plants where valve status must be checked frequently

Where NRS valves shine:

- Water distribution

- Wastewater treatment plants

- Submerged or buried installations

Installation & Maintenance Tips

For OS&Y Valves:

- Leave enough vertical space for the rising stem

- Periodically inspect and lubricate the external threads

- Use valve locks to prevent tampering, especially in public systems

For NRS Valves:

- Use external position indicators if needed

- Schedule regular checks for internal thread wear

- Apply corrosion-resistant coating for submerged systems

FAQ: OS Y Gate Valve vs Non-Rising Stem

What is an OS and Y gate valve?

It’s a type of gate valve with a stem that rises outside the valve when opened, making it easy to see whether it’s open or closed.

Is OS&Y the same as rising stem?

Yes. OS&Y is a rising stem valve where the stem visibly moves as the gate opens or closes.

What are the advantages of OS&Y valves?

Easy visual inspection, better sealing, reduced wear, and simpler maintenance.

Conclusion: Choosing the Right Valve for Your Needs

Understanding the core difference in OS Y gate valve vs non rising stem is essential to choose your system. If visibility, maintenance access, and high-reliability sealing matter, the OS&Y gate valve is your go-to. If you’re working in tight, underground, or submerged environments, the NRS gate valve offers the compact solution you need.

At PANS VALVE, we manufacture both types with precision, quality, and performance in mind. Whether you’re sourcing valves for municipal water systems, industrial steam lines, or fire safety networks, we offer a full range of NRS and OS&Y gate valves to match every application. Explore our full catalog here.

For personalized support or bulk inquiries, contact our team at PANS Valve — where quality meets innovation.

Resources

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer