What Is API 6D Standard? Everything You Need to Know

If you’re in the oil and gas or petrochemical industry, you’ve probably heard about API 6D. But what exactly does it mean? Put simply, API 6D is a globally recognized specification that sets the standard for pipeline valves. It ensures that valves meet strict performance, safety, and quality requirements—especially for long-distance pipeline systems.

This article breaks down the API 6D specification, its applications, certification scope, and how it compares to other API and ISO standards. This guide provides a clear understanding of API 6D, including everything from API 6D ball valves to certification requirements, regardless of your experience level.

Understanding API 6D: Definition and Scope

What is API 6D?

API 6D is a specification developed by the American Petroleum Institute that defines requirements for pipeline valves in petroleum and natural gas industries. It applies to ball valves, gate valves, check valves, and plug valves used in pipelines.

Three Key Takeaways:

- API 6D ensures valves are safe, durable, and capable of withstanding high-pressure pipeline systems.

- It is essential for long-distance oil and gas transmission.

- Conforms to international standards such as ISO 14313.

The API 6D specification covers aspects like design, pressure testing, dimensions, operation, and materials. This includes full-bore and reduced-bore API 6D ball valves, check valves, gate valves, and plug valves.

These valves are typically used in pipelines with critical requirements such as leak protection, emergency shutoff, and venting.

Exploring API 6D Certification and Product Benefits

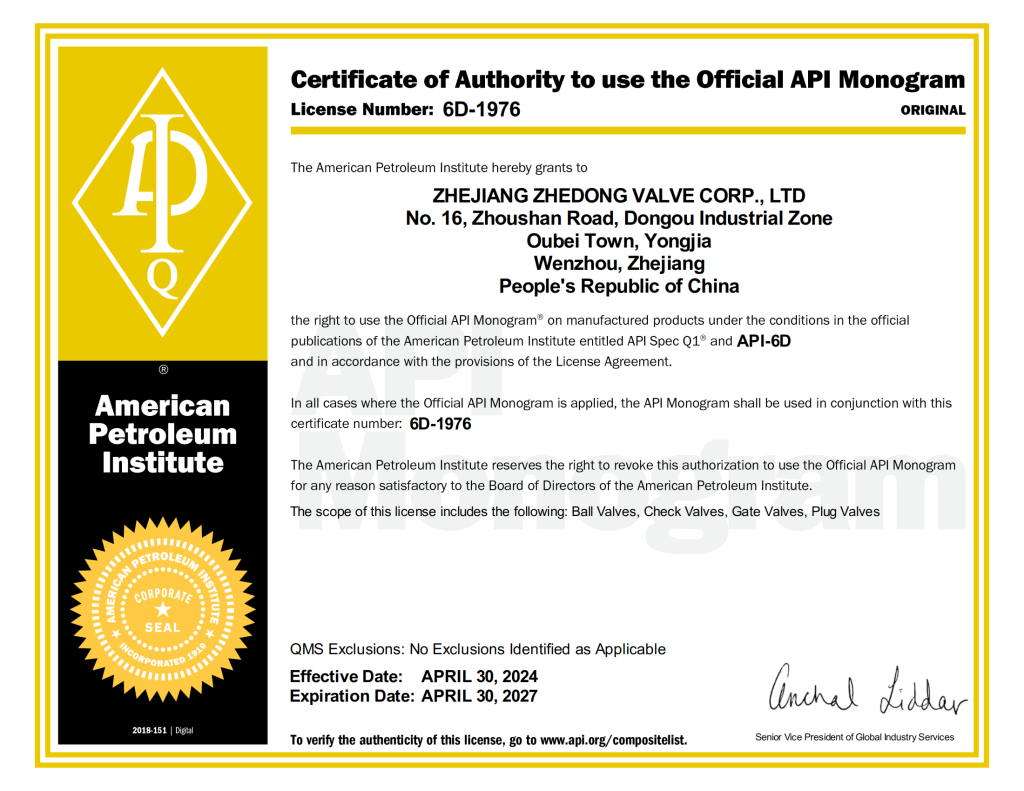

API 6D certification means that a company makes valves that are safe, strong, and high-quality. This certification comes from the American Petroleum Institute, a group that sets rules for oil and gas equipment. If a valve has API 6D, it meets top standards and can be trusted in pipelines.

What Products Can Be API 6D Certified?

According to the API 6D specification, certification applies to:

- Ball valves (floating and trunnion-mounted) with full or reduced bore

- Check valves (swing, lift, and axial flow designs)

- Gate valves (including slab and expanding gate types)

- Plug valves (lubricated and non-lubricated)

These valve types must meet defined criteria for materials, pressure ratings, dimensions, and performance. Certification includes compliance with ASME pressure classes 150 to 2500 and valve sizes ranging from NPS 2 to 60, depending on type.

Advantages of API 6D Certified Valves:

- ✔ Reliable Operation: Certified valves undergo hydrostatic shell and seat testing, per API 6D pressure testing guidelines, to ensure zero leakage under pressure.

- ✔ Enhanced Safety: Features like double block-and-bleed, emergency seat sealing, and venting systems support safe operation and maintenance.

- ✔ Regulatory Compliance: Certification aligns with international norms such as ISO 14313 vs API 6D, making them suitable for global pipeline projects.

- ✔ Traceability & Documentation: Every certified valve must include traceable material documentation and pass third-party audits.

Applying API 6D Valves in Real-world Scenarios

API 6D valves are used in vital parts of oil, gas, and energy systems. Their strict compliance with the API 6D specification makes them suitable for operations where safety, sealing, and durability are crucial.

- Oil and Gas Transmission Pipelines: API 6D valves, including API 6D ball valves and API 6D gate valves, are essential for long-distance pipelines. They offer tight sealing, resistance to pressure fluctuations, and fast shut-off in case of emergencies.

- Refineries and Petrochemical Facilities: API 6D valves withstand extreme heat, corrosive chemicals, and heavy-duty cycles, especially in high-temperature, high-pressure processing units.

- Power Generation Plants: These valves maintain critical control over steam and gas flow. API 6D valves support automated control systems that demand reliable and responsive valve actuation.

- Natural Gas Storage and LNG Terminals: API 6D check valves and plug valves ensure flow control, backflow prevention, and system safety during gas injection or withdrawal cycles.

- Compressor and Pump Stations: Installed along pipelines, API 6D-certified valves help isolate flow during maintenance or repair, reducing downtime and ensuring operational safety.

Thanks to features like double block-and-bleed, vent ports, and robust sealing, ball valves API 6D and API 6D butterfly valves are preferred in automated and remote-controlled systems where fast, leak-free operation is required.

Comparing API 6D with Other Standards

Understanding how API 6D stacks up against other standards can help you make informed decisions. Here’s a comparison table:

| Standard | Definition | Application | Valve Types Included |

| API 594 vs API 6D | API 594 covers check valves only | General purpose | Check Valves only |

| API 598 vs API 6D | API 598 focuses on valve testing | Across valve types | Testing guidelines |

| API 600 vs API 6D | API 600 is specific to gate valves | Refining & process plants | Gate Valves |

| API 608 vs API 6D | API 608 is for metal ball valves | Industrial process piping | Ball Valves |

| API 6A vs 6D | API 6A is for wellhead and Christmas tree valves | Wellhead equipment | Special purpose valves |

| ISO 14313 vs API 6D | ISO equivalent of API 6D | Global standardization | Ball, Gate, Plug, Check |

| ISO 17292 vs API 6D | ISO standard for industrial ball valves | General industrial use | Ball Valves |

Meeting API 6D Certification Requirements

To achieve API 6D certification, manufacturers must meet strict requirements set by the American Petroleum Institute:

Certification Requirements

- Design validation: Must conform to ASME and ISO standards

- Non-destructive testing (NDE): Required for pressure parts

- Hydrostatic testing: Follows API 6D pressure testing protocols

- Quality management system: Must align with ISO 9001

- Manufacturing traceability: Materials and processes must be fully traceable

Additionally, valves must be tested for performance at high and low temperatures and under varying pressure differentials. For example, API 6D pressure testing includes hydrostatic seat and shell tests and leakage and strength checks.

PANS Valve: Your Trusted API 6D Certified Manufacturer

PANS VALVE is proud to be a certified API 6D ball valve manufacturer and API 6D gate valve manufacturer. Our commitment to quality, innovation, and delivery speed makes us a trusted name in industrial valves.

Why Choose PANS?

- Certified Product Line: Ball valves, check valves, gate valves, and plug valves

- Fast Response: Drawings within 24 hours, delivery in as little as 20 days

- Wide Range: From API 6D ball valve dimensions to butterfly valve options, our catalog covers your needs. Explore our product catalog for certified valves.

- Global Compliance: Our valves meet API, CE, ISO, and TUV standards

At PANS VALVE, we’re proud to support global industries with API 6D-certified solutions that exceed expectations. With decades of manufacturing expertise and an extensive product line, we’re here to help you achieve operational reliability.

Visit our website to learn more or request a quote.

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer