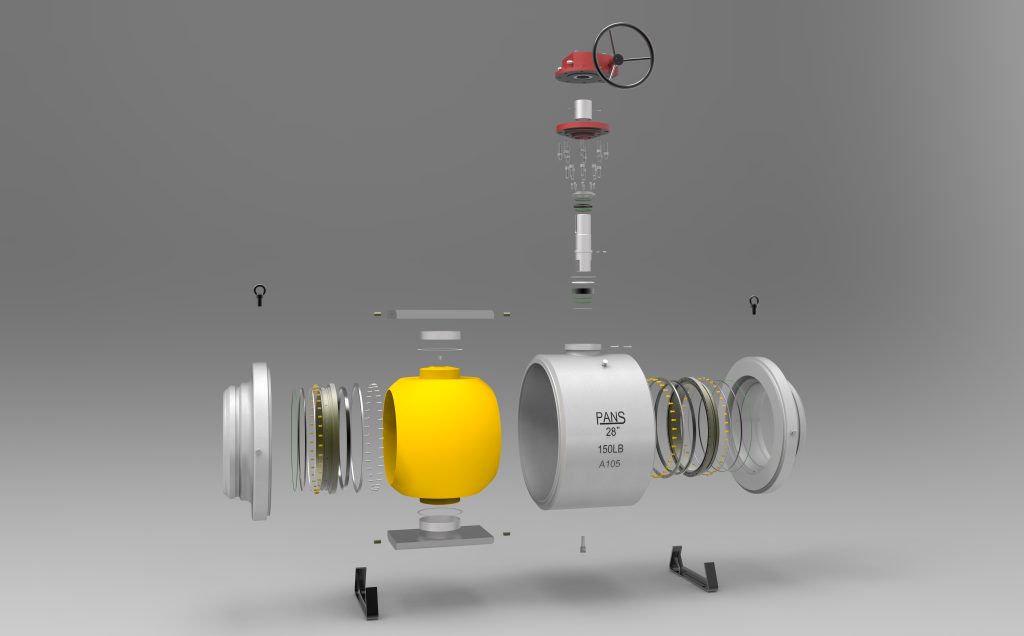

Fully Welded Ball Valve

Description

A fully welded ball valve is a type of valve that is designed with a welded and forged body, providing maximum strength at minimum weight. It is commonly used in industrial applications and is suitable for pipelines with class150-class600 and pn16-pn40 ratings. Here are some key features and advantages of fully welded ball valves:

- Construction: Fully welded ball valves are made of the same material as pipelines, which helps prevent uneven stress and deformation caused by vibrations. The welded body design eliminates several potential leak points, increasing the overall strength and durability of the valve.

- Sealing: Fully welded ball valves use a floating ball with an inclined surface that ensures the sealing ring is tightly pressed on, providing a reliable and tight seal. This design helps to prevent leakage and ensures efficient flow control.

- Strength and Resistance: The fully welded construction of these valves gives them maximum stability at minimum weight, making them suitable for high-pressure and high-temperature applications. They offer maximum resistance to pipeline pressures and internal and external loads.

- Reduced Maintenance: Fully welded ball valves have fewer potential leak points than other valves, reducing the need for frequent maintenance and repairs. This makes them a cost-effective choice for long-term use.

- Versatility: Fully welded ball valves can be used to cut off or connect the medium in pipelines, making them suitable for various applications in various industries. They are commonly used in oil and gas, petrochemical, and power generation industries.

Specifications:

- Main Standard: API 6D/ISO 14313

- Applications: Oil & Gas Transmission and distribution pipelines (also called fully welded pipeline ball valve), HIPPS, Heating supply

- Application Standard: API 6D, ISO 14313, ASME VIII, ASME B16.34, ASME B16.10, ASME B16.5, NACE MR0175 and other diffused Industry standards

- Size Range: Class 150: 2″-60″, Class 300: 2″-48″, Class 600: 2″-36″

Class 900: 2″-24″, Class 1500: 2″-20″, Class 2500: 2″-12″ - Special Test: EN 10204 Type 3.2 Material Certification by a Thirty Parts, API 641 Fugitive Emissions, PMI, NDE test.

Advantage:

- Reduced Leak Points: The fully welded body design of these valves reduces the number of potential leak points, minimizing the risk of external leakage. This enhances the overall reliability and safety of the valve.

- Maximum Strength and Resistance: Fully welded ball valves offer maximum strength at minimum weight, making them highly durable and resistant to pipeline pressures and stresses. Their robust construction allows them to withstand high-pressure and high-temperature applications.

- Compact Envelope: Fully welded ball valves have a compact envelope, which means they take up less space compared to other types of valves. This compact design allows for increased strength and a significant reduction in weight, making them easier to install and handle.

- Long Service Life: These valves are known for their superior quality and stable performance, resulting in long service lives. Their welded body construction ensures durability and reliability over extended periods of use.

- Low Maintenance: Fully welded ball valves require minimal maintenance due to their fewer potential leak points and robust construction. This reduces downtime and maintenance costs, making them a cost-effective choice for industrial applications.

Related products

Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

Globe Valve

- Cast Globe Valve

Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

Slurry Valve

- Slurry Valve